25+

Years Of

experience

experience

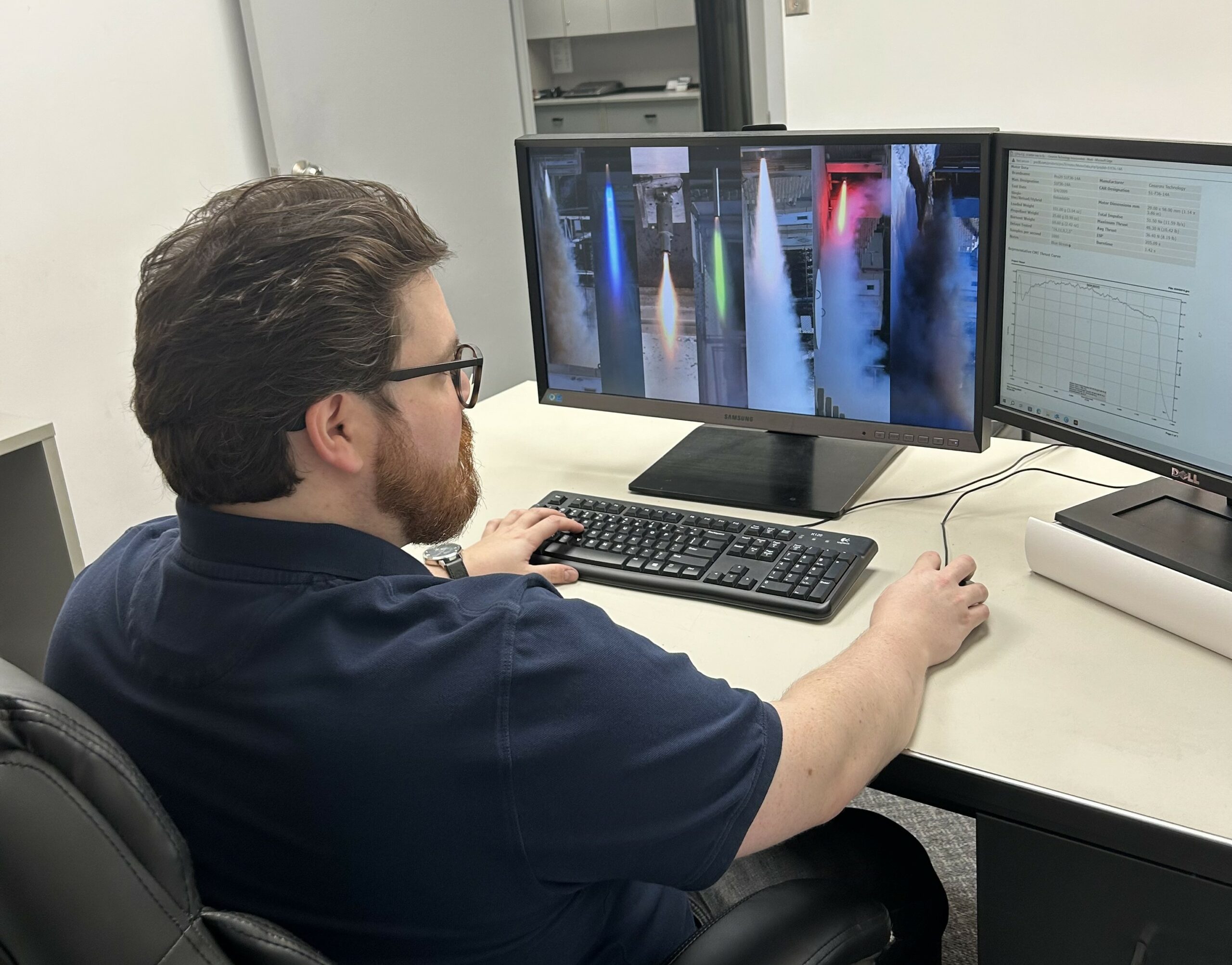

About Our Company

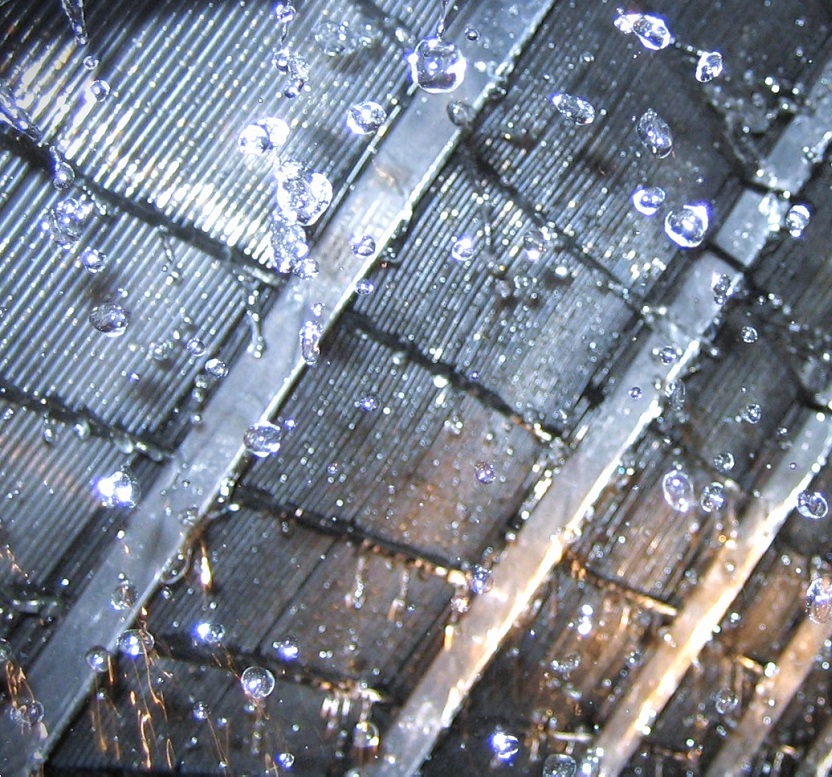

Cesaroni Technology Incorporated is at the forefront of the developing high performance polymeric heat exchanger systems, under the brand name Polycoil.

These all-plastic exchangers offer high heat transfer in a package that is corrosion free, lightweight, and durable. Currently they are available in three types: Rectangular Exchangers, Curved Exchangers, Tube & Shell.

Cesaroni Technology Inc, with over 25 years of experience, specializes in customizing and prototyping Polycoil polymer heat exchangers to meet customer needs. We are highly adaptable, offering minor modifications to our existing lineup or collaborating with you from design through production to bring your requirements to life.